Carbon Molecular Sieve, commonly called CMS, is a porous carbon material distinguished by its ability to selectively absorb molecules based on size and shape. This unique characteristic makes CMS an excellent choice for gas separation, purification, and filtration applications. Its structure features a network of micropores—tiny channels within the material—carefully sized to permit specific molecules while blocking others. Composed mainly of high-purity carbon, CMS undergoes a controlled production process to achieve the desired porous structure.

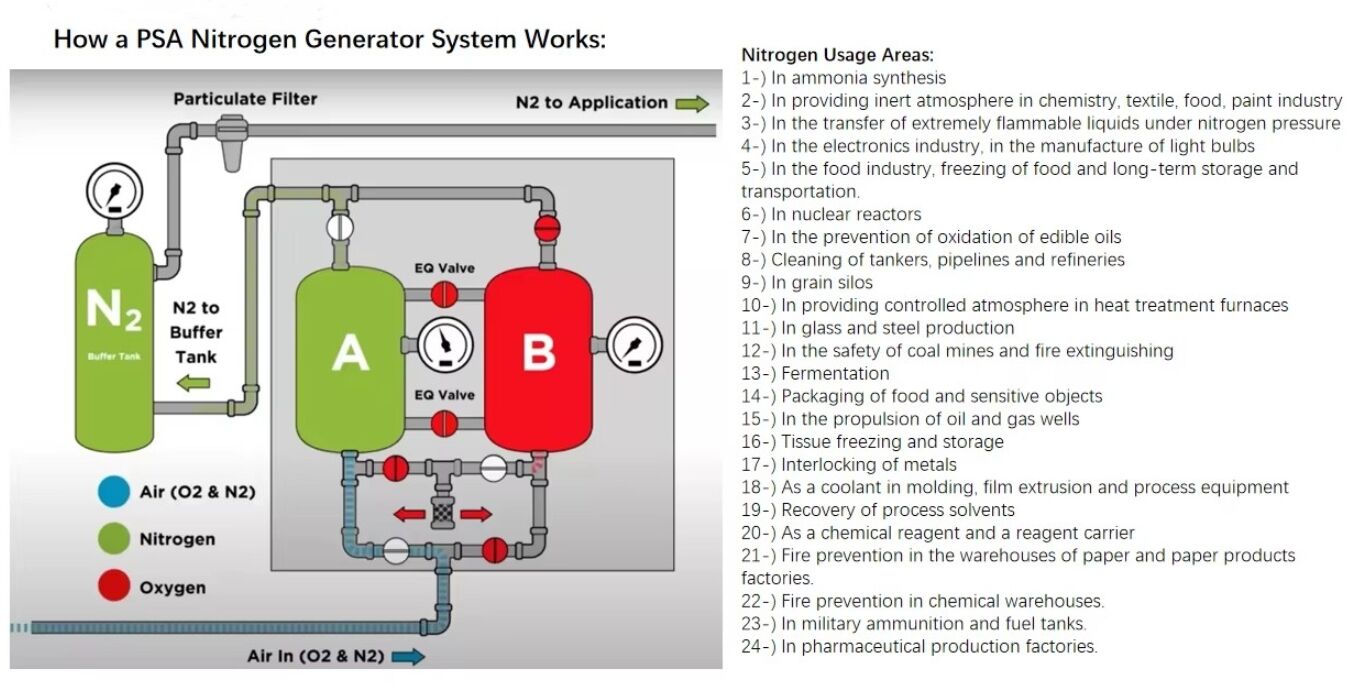

CMS takes the appearance of cylindrical black solid, contains countless 4 angstrom fine pores. It can be used to separate air into nitrogen and oxygen. In industry, CMS can concentrate nitrogen from air with PSA systems, the nitrogen(N2) purity up to 99.999%. Our CMS products have the character of large nitrogen yield capacity; high nitrogen recovery. It can meet the requirement of all types of PSA nitrogen systems. The carbon molecular sieve is widely applied in petroleum chemical industry, the heat treatment of metal, the electronic manufacture and food preservation industries.

Application:

CMS Applications: Nitrogen Generation, Gas Separation and Purification

CMS is essential in gas separation processes such as Pressure Swing Adsorption (PSA) and vacuum swing adsorption (VSA) systems. These systems leverage CMS’s capability to selectively absorb specific gas molecules, facilitating the separation and purification of gases.

CMS plays an important role in nitrogen generation systems, utilizing its capacity to capture oxygen and other impurities selectively, resulting in the production of high-purity nitrogen from compressed air. Furthermore, CMS is integral to air purification systems, effectively eliminating impurities such as carbon dioxide, moisture, and hydrocarbons.

Technical indicators:

|

Particle diameter |

1.2- 1.4mm |

|||

|

Adsorption cycle |

2 × 45s |

|||

|

Bulk density |

630-670 g/L |

|||

|

Compressive strength |

≥75 n/piece |

|||

|

Test temperature |

≤20 °C |

|||

|

|

|

|

|

|

|

Model |

Adsorption Pressure (Mpa) |

Nitrogen Purity % |

Nitrogen Production Volume (m3/Mt.Ht) |

Air To Nitrogen Ratio |

|

CMS 220 |

0.6-0.8 |

99 |

290 |

48 |

|

99.5 |

220 |

43 |

||

|

99.9 |

160 |

34 |

||

|

99.99 |

90 |

25 |

||

|

CMS 240 |

0.6-0.8 |

99 |

300 |

49 |

|

99.5 |

240 |

44 |

||

|

99.9 |

175 |

35 |

||

|

99.99 |

100 |

26 |

||

|

CMS 260 |

0.6-0.8 |

99 |

305 |

2.5 |

|

99.5 |

260 |

2.7 |

||

|

99.9 |

170 |

3.6 |

||

|

99.99 |

105 |

4.2 |

||

|

CMS 280 |

0.6-0.8 |

99 |

320 |

2.4 |

|

99.5 |

280 |

2.6 |

||

|

99.9 |

190 |

3.4 |

||

|

99.99 |

120 |

4 |

||

|

99.999 |

75 |

6.1 |

||

|

CMS 300 |

0.6-0.8 |

99 |

345 |

2.3 |

|

99.5 |

300 |

2.5 |

||

|

99.9 |

200 |

3.3 |

||

|

99.99 |

130 |

3.8 |

||

|

99.999 |

90 |

5.9 |

||

|

CMS 330 |

0.6-0.8 |

99 |

370 |

2.2 |

|

99.5 |

330 |

2.4 |

||

|

99.9 |

230 |

3.2 |

||

|

99.99 |

150 |

3.7 |

||

|

99.999 |

100 |

5.7 |

||

Notice:

If possible,reduce the adsorption temperature can performance a better production of nitrogenit should be sealed to avoid of contamination and adsorption ofwater or other gas and vapors.Storage in a drywarehouseis recommended.

Package:

Packing:20kg/barrel,40kg/barrel or as request

Our friendly team would love to hear from you!