Don't know how to choose activated carbon for municipal water treatment?

Why Proper Activated Carbon Selection Matters for Municipal Systems

The Critical Role in Water Safety Compliance

Meeting regulatory standards is crucial for municipal water systems to ensure public health. The EPA and CDC have set rigorous guidelines that dictate the quality and safety of drinking water. Activated carbon, renowned for its adsorption capabilities, plays a pivotal role in purifying municipal water supplies by removing contaminants like chlorine, volatile organic compounds (VOCs), and other hazardous substances. Effective filtration is critical, as waterborne illnesses such as gastrointestinal infections directly result from inadequate treatment. According to the CDC, approximately 7.15 million Americans suffer annually from illnesses caused by pathogens in water systems, illustrating the significant impact a reliable activated carbon system can have in preventing such outbreaks and adhering to safety standards.

Consequences of Incorrect Media Choices

Choosing the wrong filtration media can have dire consequences for municipalities, including public health risks and legal challenges. For example, using suboptimal activated carbon that cannot effectively capture specific contaminants might lead to elevated risks of exposure to harmful chemicals, causing community health issues and potential lawsuits against municipal authorities. There are cases where incorrect media choices have resulted in contamination events, leading to financial setbacks due to fines or costly remediation efforts. Additionally, this negligence can erode public trust and heighten environmental risks, with untreated contaminants potentially infiltrating local ecosystems. It is imperative that municipal systems prioritize selecting appropriate activated carbon solutions, tailored to meet their specific water treatment needs and comply with regulatory standards, for both public health and environmental sustainability.

Key Selection Criteria for Municipal Water Treatment

Identifying Target Contaminants: Organics vs. Disinfection Byproducts

Municipal water treatment requires a keen understanding of the difference between organic contaminants and disinfection byproducts. Organic contaminants include substances like pesticides, herbicides, and volatile organic compounds (VOCs), which originate from agricultural and industrial runoff. In contrast, disinfection byproducts, such as trihalomethanes (THMs) and haloacetic acids (HAAs), result from the reaction between organic matter in the water and disinfectants like chlorine. Municipalities must target these contaminants effectively to ensure safe drinking water. Research indicates that organic compounds are prevalent in many municipal water supplies due to increased industrial activities, while disinfection byproducts frequently occur due to the chlorination process used for sterilization.

Matching Molecular Weight to Carbon Pore Structure

The effectiveness of carbon adsorption in water treatment relies heavily on the molecular weight of the contaminants and the pore structure of the activated carbon. Contaminants with smaller molecular weights are best adsorbed by micropores, while those with larger molecules, like VOCs, need mesopores or even macropores. Micropores are less than 2 nanometers, mesopores range from 2 to 50 nanometers, and macropores exceed 50 nanometers. Literature suggests that selecting the right pore structure is critical because it determines the carbon's ability to adsorb specific contaminants, ensuring effective treatment. Understanding this relationship is vital for optimizing the purification process and achieving regulatory compliance.

Adsorption Metrics: Iodine Value & Methylene Blue Tests

Iodine value and methylene blue tests are standard metrics for evaluating the quality of activated carbon used in water treatment. The iodine value reflects the amount of micropore content available for adsorption, which directly relates to the carbon's efficacy in removing small organic compounds. On the other hand, the methylene blue test indicates the carbon's capability to adsorb larger molecules. These benchmarks are crucial for operational efficiency and the effectiveness of contaminant removal. Studies have shown a positive correlation between high iodine values and superior performance in municipal settings, which illustrates the importance of selecting high-quality activated carbon for municipal water systems.

Particle Size Optimization (8-30 Mesh)

Optimizing the particle size of activated carbon is essential for maximizing the surface area available for adsorption, directly influencing the filtration effectiveness. The mesh size range of 8-30 is often used, as it balances surface area with the pressure drop required for water to flow through the filter. Larger mesh sizes offer faster flow rates with lower pressure drops, benefiting operational performance but may sacrifice some adsorption capacity. Optimal particle size also reduces clogging risks and ensures efficient contaminant removal. Empirical data suggests that specific mesh sizes work best for particular contaminants, highlighting the need for careful selection based on the treatment goals and water quality conditions.

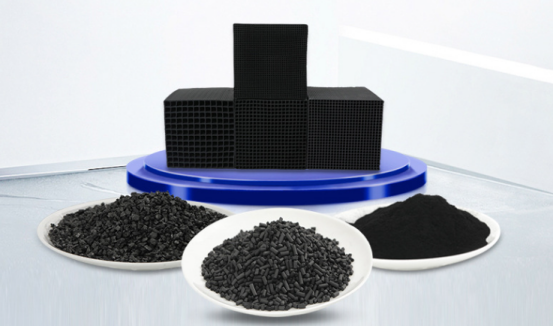

Granular vs. Powdered Activated Carbon: Application Breakdown

GAC Fixed-Bed Design for Continuous Operations

Granular Activated Carbon (GAC) systems are a mainstay in municipal water treatment, especially for continuous operations. The design of these systems requires precise considerations, including optimal contact time and flow rate, to ensure effective treatment performance. It is crucial to balance these factors to facilitate adequate adsorption of contaminants while maintaining cost efficiency. Studies in the field have shown that properly designed GAC systems provide robust performance with high removal rates of organic contaminants and chlorine in long-term municipal settings. This makes them an indispensable component of water purification frameworks in cities.

PAC Advantages in Emergency Contamination Events

Powdered Activated Carbon (PAC) is highly effective during emergency contamination events. Its rapid adsorption capability ensures that it can quickly neutralize pollutants, providing a swift solution to unforeseen water quality issues. Several case studies have highlighted the successful deployment of PAC during crises, including incidents of chemical spills and industrial accidents. Regulatory bodies and municipal reports further substantiate the role of PAC in emergency settings, noting its speed and efficiency in contaminant removal compared to traditional methods. This makes PAC an essential asset in municipal emergency response arsenals.

Backwash Cycle Calculations for GAC Systems

Maintaining the performance of GAC systems requires regular backwashing to manage sediment levels and preserve efficiency. Calculating accurate backwash cycles is critical, typically based on the specific demands of the system, such as influent quality and operational flow rates. Industry standards often recommend backwash intervals that ensure optimal GAC performance by preventing clogging and media degradation. For example, data from water treatment guidelines suggest backwash frequencies ranging from weekly to bi-weekly, depending on the contaminant load. Proper backwash cycle management is integral to the sustained success of GAC systems in municipal applications.

5-Step Systematic Selection Process

Water Quality Analysis and Pollutant Profiling

The first step in choosing the right activated carbon is a comprehensive water quality analysis and pollutant profiling. This involves identifying the specific contaminants present in the water, which can vary significantly depending on the source. Accurate pollutant profiling ensures that the chosen activated carbon effectively targets the main contaminants. Common methodologies include using analytical tools such as gas chromatography and mass spectrometry to detect volatile compounds and heavy metals. According to benchmarks set by environmental organizations like the EPA, pollutants must fall within specific limits to be deemed safe. Therefore, a precise understanding of all present pollutants is crucial in the selection process to ensure compliance and effective treatment.

Contact Time Calculations (EBCT Optimization)

Understanding Empty Bed Contact Time (EBCT) is crucial for optimizing activated carbon adsorption efficacy. EBCT is the time duration that water is in contact with activated carbon, which directly affects contaminant removal efficiency. For instance, different applications require varying EBCTs; municipal water treatment might require an EBCT of 10-15 minutes, whereas industrial applications may need a different time frame. Research indicates a strong correlation between optimal contact time and successful contaminant removal, such as studies where increased EBCT led to higher removal rates of organic compounds. Therefore, accurate calculations of contact time are necessary to tailor the system for effective performance.

Cost-Benefit Analysis: Initial vs. Regeneration Costs

A thorough cost-benefit analysis is essential in evaluating the financial implications of using activated carbon in municipal systems. This analysis involves comparing initial setup costs with long-term regeneration expenses to determine the total cost of ownership. While the initial installation might seem expensive, regeneration strategies can significantly reduce ongoing expenses by rejuvenating spent carbon for reuse. For example, some municipalities have implemented successful regeneration strategies that balance up-front costs with lifecycle savings. By analyzing both costs, municipalities can make informed decisions that ensure economic viability alongside treatment efficacy.

Supplier Certification Checklist (ASTM Standards)

Supplier certifications and adherence to ASTM standards play a critical role in the procurement of activated carbon. These certifications ensure quality and reliability, which directly impact the efficacy of water treatment systems. Municipalities should use a checklist to evaluate potential suppliers, focusing on compliance with ASTM International guidelines. Quality assurance from certified suppliers has been shown to affect treatment efficacy positively, as certified products typically perform consistently under varying conditions. This adds a layer of accountability and assurance in the procurement process, ensuring that the highest standards are met for effective water treatment.

Avoiding Common Municipal Selection Mistakes

Myth: Higher Iodine Value Guarantees Better Performance

It's a common misconception that a higher iodine value ensures superior performance of activated carbon. However, this myth can lead municipalities to select carbon types that are not optimally suited for their specific needs. Iodine value is an indication of the carbon's micro porosity, primarily signifying its capacity to adsorb small molecules. Factors such as surface area, pore size distribution, and the nature of the contaminants play a crucial role in the performance efficacy. For instance, a municipal facility may choose an activated carbon with a higher iodine number, expecting better removal of various contaminants, but end up with suboptimal choices for larger molecules or specific pollutants. Effective carbon selection must go beyond assuming that higher iodine values automatically translate into better performance.

Overlooking Particle Size Distribution Impacts

The particle size distribution of activated carbon significantly influences its effectiveness in treatment processes. Smaller particles increase the surface area available for adsorption, but they may result in higher pressure drops and operational challenges in filtration systems. Neglecting this aspect can result in poor treatment outcomes, as the activated carbon might not remove contaminants efficiently. For example, a case study from a municipal water treatment plant showed that ignoring the variability in particle sizes led to inadequate removal of trihalomethanes (THMs), compromising water quality. Optimal particle size distribution must be considered to ensure a balanced performance without compromising flow and filtration efficiency. Therefore, municipalities must engage in thorough assessments of particle size ranges before choosing the activated carbon for their systems.

Neglecting Breakthrough Curve Monitoring Protocols

Breakthrough curve monitoring is essential for ensuring continuous and optimal performance of carbon filtration systems. This curve represents the point at which the effluent concentration of a contaminant equals its influent concentration, indicating the carbon's adsorption capacity is exhausted. Establishing robust monitoring protocols allows municipalities to preemptively regenerate or replace the carbon before a breakthrough occurs, preventing contamination. Best practices include regular sampling and real-time analytics to track adsorption efficiencies and predict breakthrough points. Industry examples, such as the failure of a municipal system that delayed monitoring, resulted in elevated levels of pollutants returning to the water supply, highlight the potential consequences of overlooked monitoring. Therefore, having a proactive monitoring protocol is critical to maintaining effective water treatment operations.

EN

EN