Five reasons why wood - based activated carbon is popular in food processing

The Central Role of Activated Carbon in Food Industry Purification

Meeting Critical Needs: Impurity Removal & Decolorization

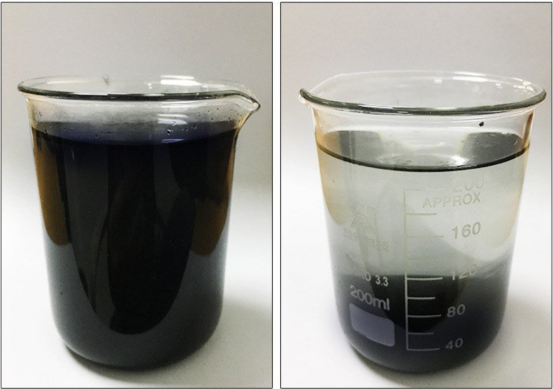

Activated carbon is vital in the food industry for the effective removal of impurities, particularly in liquid products such as juices and oils. Its highly porous structure allows for the capture of a wide range of particles, contributing to the maintenance of high purity standards. For instance, its ability to adsorb small and large particles makes it indispensable in various purification processes. Decolorization emerges as another crucial function, where activated carbon absorbs unwanted coloring agents, thereby enhancing the aesthetic appeal of food products. Case studies from beverage manufacturers often highlight significant reductions in color when activated carbon is employed. Additionally, the reduction of impurities facilitated by activated carbon plays a pivotal role in helping manufacturers comply with stringent food safety regulations.

Odor Neutralization Challenges in Modern Processing

Odor neutralization is a substantial challenge in food processing, as unpleasant smells can detrimentally affect product acceptability. Activated carbon, with its porous structure, effectively tackles this issue by adsorbing volatile organic compounds (VOCs) responsible for these odors. Industries like dairy and meat processing frequently report heightened consumer satisfaction following the implementation of activated carbon filters that successfully eliminate intense odors. Research and case studies demonstrate the measurable impact activated carbon can have on odor reduction thresholds, significantly enhancing the quality of food products. Consequently, its use in modern food processing environments is increasingly recognized as beneficial in maintaining high standards of consumer appeal and product integrity.

Products Utilizing Activated Carbon

In the context of food industry purification, several products utilize activated carbon to meet critical needs:

- Powdered Activated Carbon: Widely used for its fine particle size and enhanced adsorption efficiency, making it suitable for applications like water treatment and food processing.

- Granular Activated Carbon: Known for large-scale applications including decolorization in food and beverage products, effectively improving aesthetic quality.

- Activated Carbon Filters: Designed to remove impurities and neutralize odors in products such as dairy, juices, and oils, thereby ensuring compliance with industry standards.

Microstructure Advantage of Wood-Based Activated Carbon

Wood-based activated carbon is characterized by its superior porous microstructure that efficiently adsorbs pigment, odor, and heavy metals. Industry research reveals that the unique pore distribution in wood-derived carbons enables heightened adsorption rates and capacities compared to coal and coconut shell counterparts. Furthermore, these properties comply with international food-grade certification standards such as FDA and EFSA, enhancing credibility and trust in food processing applications.

Renewability of Wood Sources and the Carbon Footprint

Leveraging wood sources, including forestry by-products, reflects a commitment to sustainable practices. The production process for wood-based activated carbon encompasses significantly lower energy consumption, resulting in a reduced carbon footprint compared to traditional activated carbon methods. This aligns seamlessly with the ESG objectives of food enterprises, underpinning their environmental, social, and governance commitments with eco-friendly material choices.

Economic Advantages in Industrial-Scale Use

The ready availability of raw materials for wood-based activated carbon offers a financial advantage over petroleum-based adsorbents, lowering production costs. High recycling utilization capability notably diminishes long-term expenses, as seen in applications like edible oil refining. The stability of these materials is evident in large-scale applications, such as beverage decolorization lines, where efficiencies become more pronounced.

Preserving Sensory Qualities in Processed Foods

Activated carbon's chemical inertness ensures that food ingredients remain unaffected, preserving pH stability in products like juices. The non-reactive nature of these materials safeguards natural nutrients, contrasting with chemical decolorants that may degrade vitamins. In specific contexts, such as beer brewing, activated carbon effectively removes impurities without compromising the malt aroma or flavor, supporting authentic sensory experiences in processed food offerings.

Adaptability to Evolving Industry Requirements

With customizable particle sizes, activated carbon demonstrates adaptability for diverse applications, enhancing filtration solutions for specific processing needs. As the industry evolves, emerging contaminant removal, including microplastics and pharmaceuticals, highlights the relevant applications of activated carbon for future-proofing food production processes. This ensures manufacturers remain compliant with health, safety, and environmental regulations as they advance.

EN

EN