کاربن مالیکیولر چھلنی ، عام طور پر CMS کہا جاتا ہے، ایک پوروس کاربن مواد ہے جو سائز اور شکل کی بنیاد پر سالموں کو انتخابی جذب کرنے کی صلاحیت سے ممتاز ہے۔ یہ منفرد خصوصیت سی ایم ایس کو گیس علیحدگی، صاف کرنے اور فلٹریشن ایپلی کیشنز کے لئے ایک بہترین انتخاب بناتی ہے۔ اس کی ساخت میں مواد کے اندر مائکروپوریٹین چینلز کا ایک نیٹ ورک ہے جو احتیاط سے سائز میں ہے تاکہ مخصوص مالیکیولز کو اجازت دی جاسکے جبکہ دوسروں کو روک دیا جاسکے۔ بنیادی طور پر اعلی طہارت کاربن سے بنا ہوا، CMS مطلوبہ porous ساخت حاصل کرنے کے لئے ایک کنٹرول پیداوار کے عمل سے گزرتا ہے.

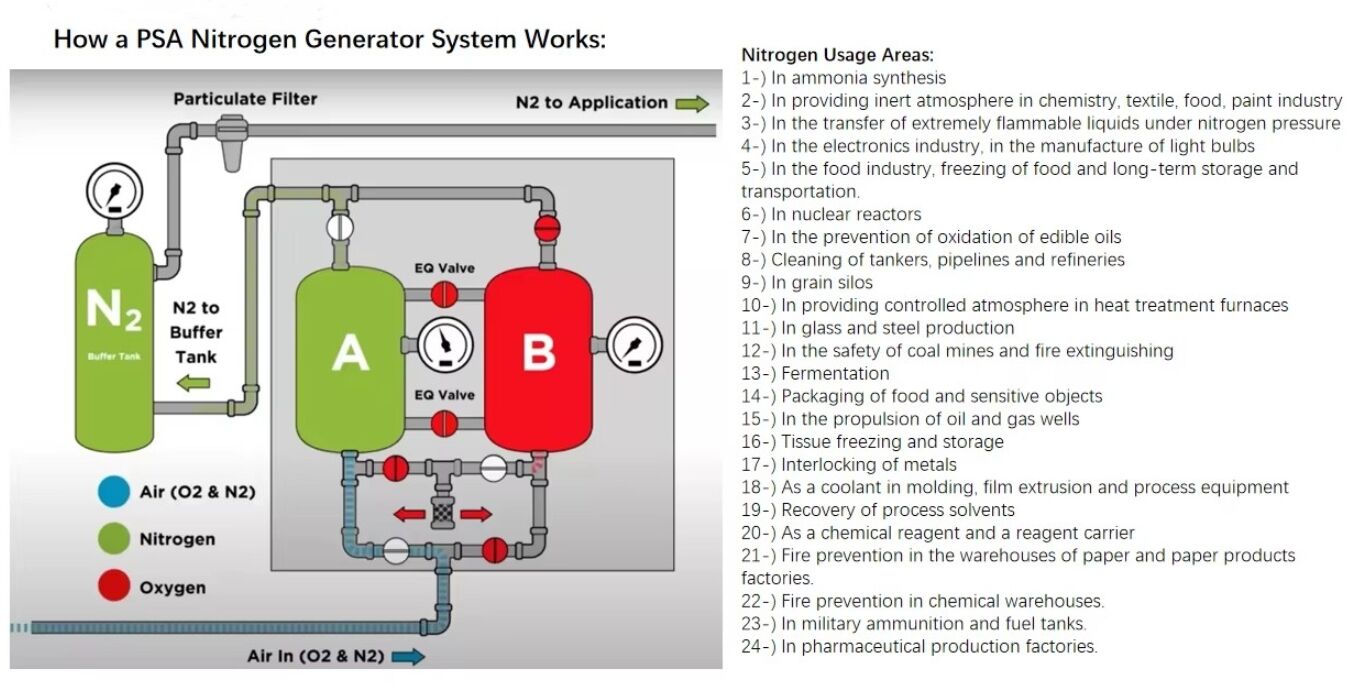

CMS سلنڈر کی شکل میں سیاہ ٹھوس ہے، بے شمار 4 angstrom ٹھیک pores پر مشتمل ہے. اس سے ہوا کو نائٹروجن اور آکسیجن میں الگ کرنے کے لئے استعمال کیا جاسکتا ہے۔ صنعت میں، سی ایم ایس پی ایس اے سسٹم کے ساتھ ہوا سے نائٹروجن کو مرکوز کر سکتا ہے، 99.999٪ تک نائٹروجن (N2) پاکیزگی. ہماری CMS مصنوعات میں نائٹروجن کی بڑی پیداوار کی صلاحیت ہے۔ نائٹروجن کی اعلی بازیابی۔ یہ PSA نائٹروجن کے نظام کی تمام اقسام کی ضرورت کو پورا کر سکتے ہیں. کاربن مالیکیولر سائیٹ پٹرولیم کیمیائی صنعت، دھات کے حرارتی علاج، الیکٹرانک مینوفیکچرنگ اور کھانے کی حفاظت کی صنعتوں میں وسیع پیمانے پر لاگو کیا جاتا ہے.

درخواست:

CMS ایپلی کیشنز: نائٹروجن جنریشن، گیس علیحدگی اور صافی

سی ایم ایس گیس علیحدگی کے عمل میں ضروری ہے جیسے پریشر سوئنگ جذب (پی ایس اے) اور ویکیوم سوئنگ جذب (وی ایس اے) کے نظام. یہ نظام سی ایم ایس کی صلاحیت کو منتخب طور پر مخصوص گیس مالیکیول کو جذب کرنے کے لئے فائدہ اٹھاتے ہیں، گیسوں کی علیحدگی اور صفائی کو آسان بناتے ہیں.

سی ایم ایس نائٹروجن جنریشن سسٹم میں اہم کردار ادا کرتا ہے ، جس سے آکسیجن اور دیگر نجاستوں کو انتخابی طور پر پکڑنے کی صلاحیت کا استعمال ہوتا ہے ، جس کے نتیجے میں کمپریسڈ ہوا سے اعلی طہارت والے نائٹروجن کی پیداوار ہوتی ہے۔ اس کے علاوہ، سی ایم ایس ہوا صاف کرنے کے نظام کا لازمی جزو ہے، مؤثر طریقے سے کاربن ڈائی آکسائیڈ، نمی، اور ہائیڈروکاربن جیسے ناپاکی کو ختم کرتا ہے.

تکنیکی اشارے:

|

ذرہ قطر |

1.2 سے 1.4 ملی میٹر |

|||

|

جذب کا دورانیہ |

2 × 45s |

|||

|

بلک کثافت |

630-670 جی/ایل |

|||

|

دباو کی مزبوطی |

≥75 n/پیسے |

|||

|

ٹیسٹ کا درجہ حرارت |

≤20 °C |

|||

|

|

|

|

|

|

|

ماڈل |

جذب کا دباؤ (ایم پی اے) |

نائٹروجن کی پاکیزگی % |

نائٹروجن کی پیداوار کا حجم (m3/Mt.Ht) |

ہوا سے نائٹروجن کا تناسب |

|

CMS 220 |

0.6-0.8 |

99 |

290 |

48 |

|

99.5 |

220 |

43 |

||

|

99.9 |

160 |

34 |

||

|

99.99 |

90 |

25 |

||

|

CMS 240 |

0.6-0.8 |

99 |

300 |

49 |

|

99.5 |

240 |

44 |

||

|

99.9 |

175 |

35 |

||

|

99.99 |

100 |

26 |

||

|

CMS 260 |

0.6-0.8 |

99 |

305 |

2.5 |

|

99.5 |

260 |

2.7 |

||

|

99.9 |

170 |

3.6 |

||

|

99.99 |

105 |

4.2 |

||

|

CMS 280 |

0.6-0.8 |

99 |

320 |

2.4 |

|

99.5 |

280 |

2.6 |

||

|

99.9 |

190 |

3.4 |

||

|

99.99 |

120 |

4 |

||

|

99.999 |

75 |

6.1 |

||

|

CMS 300 |

0.6-0.8 |

99 |

345 |

2.3 |

|

99.5 |

300 |

2.5 |

||

|

99.9 |

200 |

3.3 |

||

|

99.99 |

130 |

3.8 |

||

|

99.999 |

90 |

5.9 |

||

|

CMS 330 |

0.6-0.8 |

99 |

370 |

2.2 |

|

99.5 |

330 |

2.4 |

||

|

99.9 |

230 |

3.2 |

||

|

99.99 |

150 |

3.7 |

||

|

99.999 |

100 |

5.7 |

||

نوٹس :

اگر ممکن ہو تو،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ کر سکتے ہیں،اس میں اضافہ

پیکج:

پیکنگ:20kg/barrel،40kg/barrel یا درخواست کے مطابق

ہمارا دوستانہ ٹیم آپ سے ملنا چاہتی ہے!